Diamond Wheels

Overview

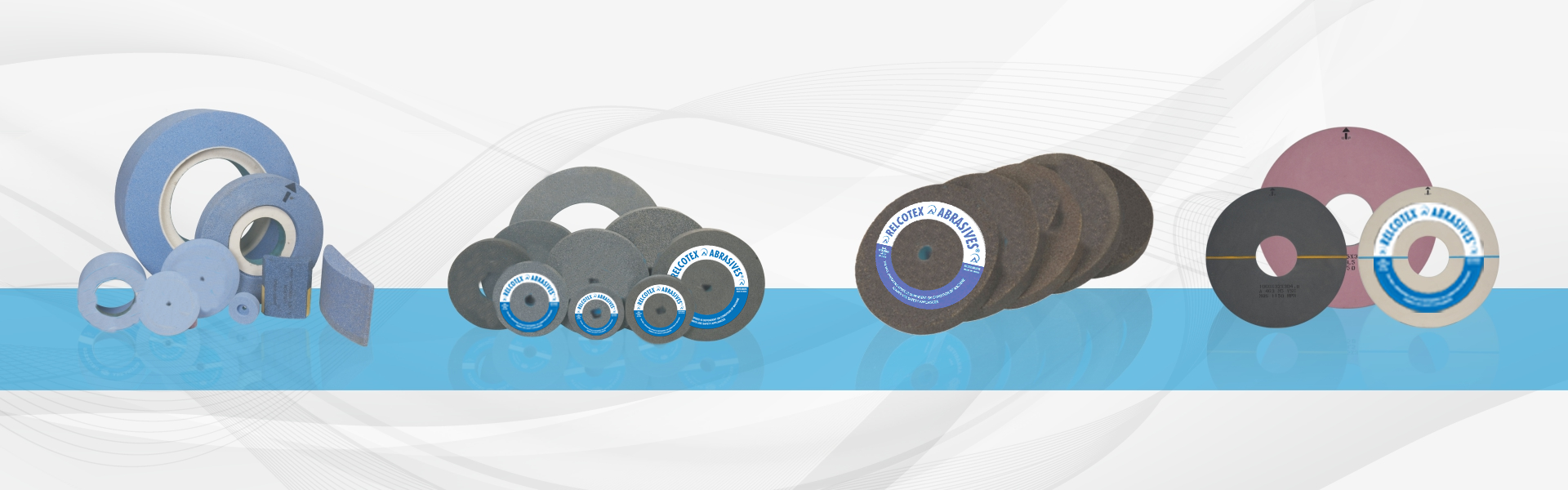

Relcotex Abrasives offers premium-quality Diamond Wheels for precision grinding, cutting, and shaping applications. These wheels are engineered with high-grade diamond grains and advanced bonding systems to deliver superior performance, durability, and accuracy in the most demanding industrial operations.

Features

- High Precision: Ensures accurate cutting and grinding with minimal material wastage.

- Superior Durability: Made with premium diamond grains for extended tool life.

- Excellent Heat Resistance: Operates efficiently at high temperatures without degradation.

- Smooth Finishing: Provides a flawless surface finish, reducing post-grinding polishing requirements.

- Versatile Applications: Suitable for grinding hard materials such as carbide, ceramics, glass, and gemstones.

Applications

- Tool and Cutter Grinding: Ideal for sharpening carbide-tipped tools and inserts.

- Optical Industry: Perfect for grinding lenses and optical components.

- Gemstone Cutting: Precision cutting and polishing of diamonds and other gemstones.

- Ceramics and Glass Processing: Efficiently shapes and smoothens hard, brittle materials.

- Aerospace and Automotive: Used for precision grinding of high-strength components.

Specifications

- Abrasive Type: Synthetic Diamond

- Bonding Type: Resin, Metal, or Electroplated bonds available

- Shapes: Straight, Cup, and Dish Wheels

- Grit Sizes: Coarse to Ultra-Fine (customized based on application)

- Dimensions: Available in standard and custom sizes as per client requirements

Advantages

- Exceptional cutting speed and material removal rate.

- Reduced downtime due to longer wheel life.

- Enhanced precision for critical applications.

- Low vibration and noise during operation.

Professionals across industries trust Relcotex Abrasives’ Diamond Wheels for their unmatched quality, precision, and performance. Whether for industrial use or fine craftsmanship, these wheels always deliver consistent and reliable results.